Committed to provide Quality Products

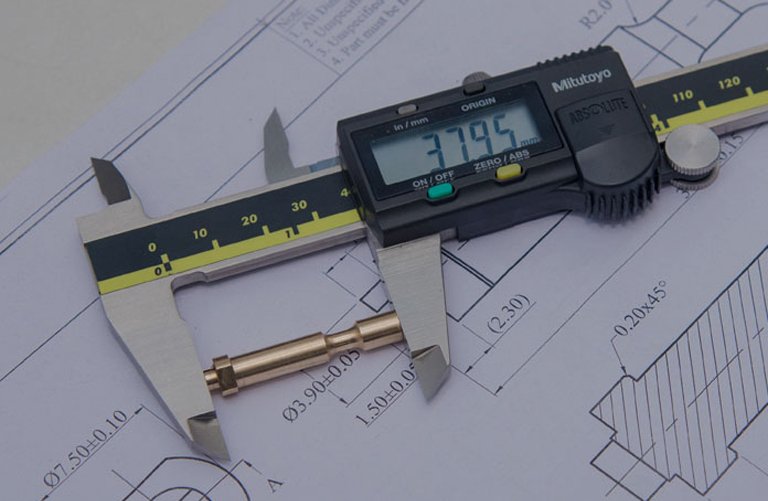

Our target is to provide zero defects products to client which is remarkable in industry. To meet the global demand we take care at every stage right from raw material purchase to finished goods. Our quality assurance team is trained and well experienced.

To achieve the maximum standard our quality control team continuously monitors the products and user requirement right from the production stage up to the final dispatch. Due to strict quality control procedures our customers are ensured that their requirements are met accurately and consistency each & every piece is inspected under strict quality control manuals.